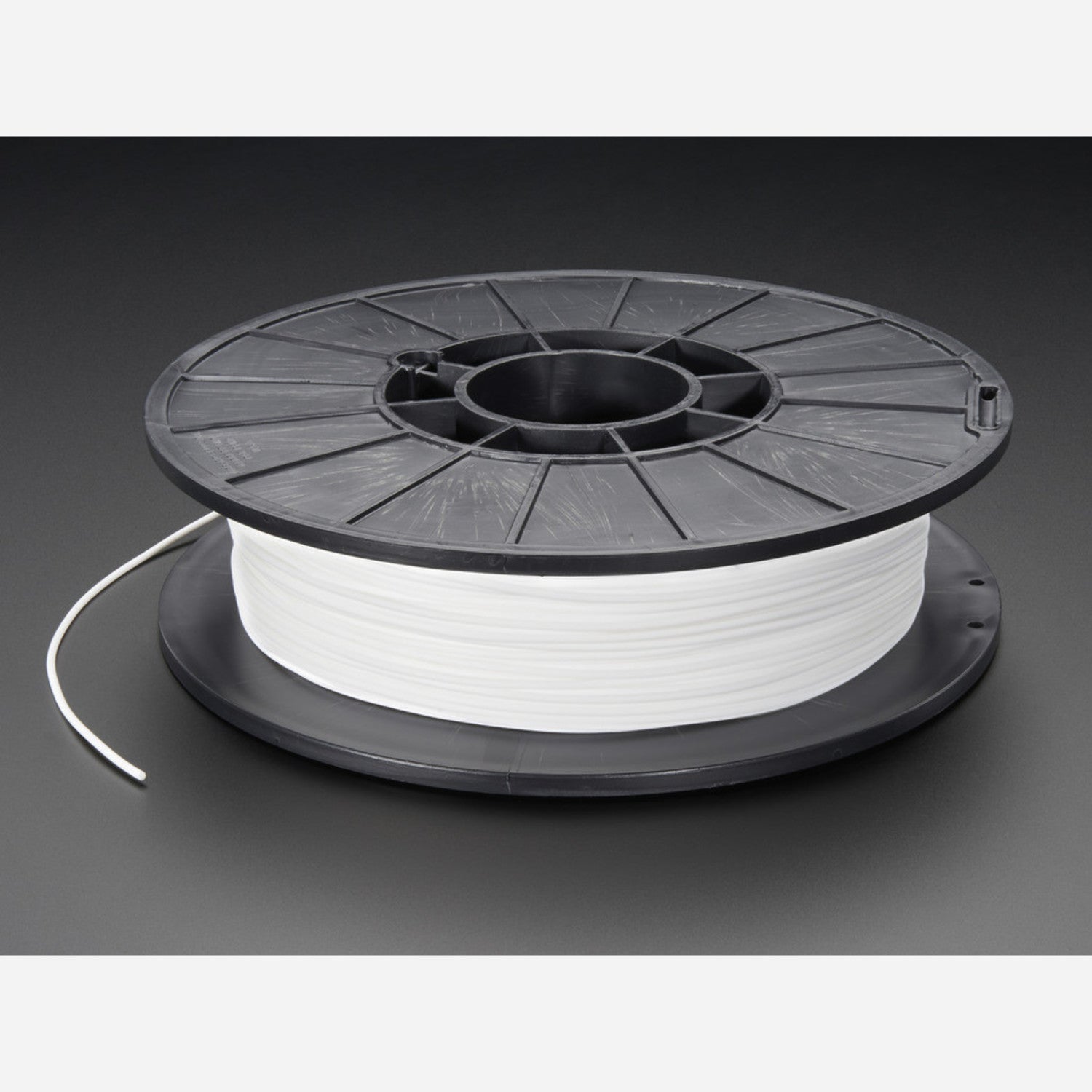

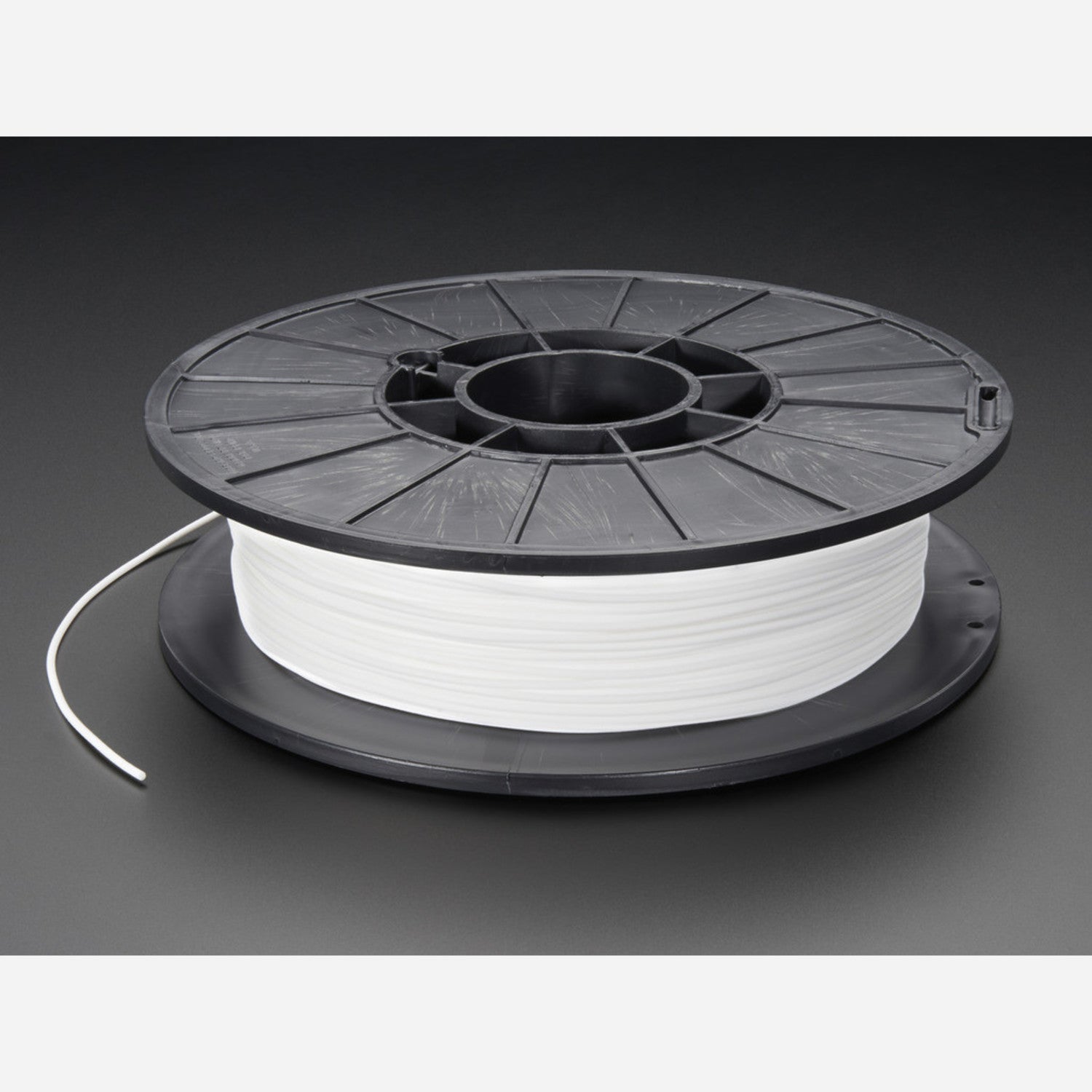

Are you tired of using ABS and PLA filaments? NinjaFlex opens up a world of endless possibilities, limited only by your imagination. It's a state - of - the - art 3D printer filament, a specially formulated thermoplastic elastomer (TPE) that creates flexible prints with great elastic properties. Its patent - pending technology ensures smooth feeding and high - quality printed parts.

NinjaFlex's unique flexibility and smooth - feeding feature allow you to create things you've never dreamed of. It's perfect for fused deposition 3D printers using 1.75mm or 3mm filaments and printers that accept other filaments like ABS and PLA.

Features:

- Filament shore hardness around 85A.

- Consistent diameter and material properties for reliable, high - quality prints.

- Smooth feeding with patent - pending technology.

- Low tack and low CoF exterior for easy feed through guides.

- High elasticity and excellent abrasion resistance.

- Good build platform adhesion and inter - layer bonding.

- Compliant with REACH and RoHS 2002/95/EC Directive.

- 1.75mm filament spool weighs 0.5 kg.

Processing Guidelines:

- Recommended extruder temperature: 210 - 225°C.

- Recommended platform temperature: 30 - 40°C.

Using NinjaFlex is a breeze. First, make sure your 3D printer is compatible with 1.75mm filaments. Then, set your extruder temperature between 210 - 225°C and the platform temperature between 30 - 40°C as recommended. Feed the filament smoothly through the guides and start your 3D printing project.

When handling NinjaFlex, keep in mind that it has low tack and low CoF exterior, so it should pass through the guides easily. If you encounter any feeding issues, check the extruder temperature and make sure it's within the recommended range.

For maintenance, store the filament in a cool, dry place to keep its properties consistent. And always ensure that your printer is clean before using NinjaFlex to get the best printing results. With proper use and care, NinjaFlex will give you high - quality, flexible 3D prints every time.