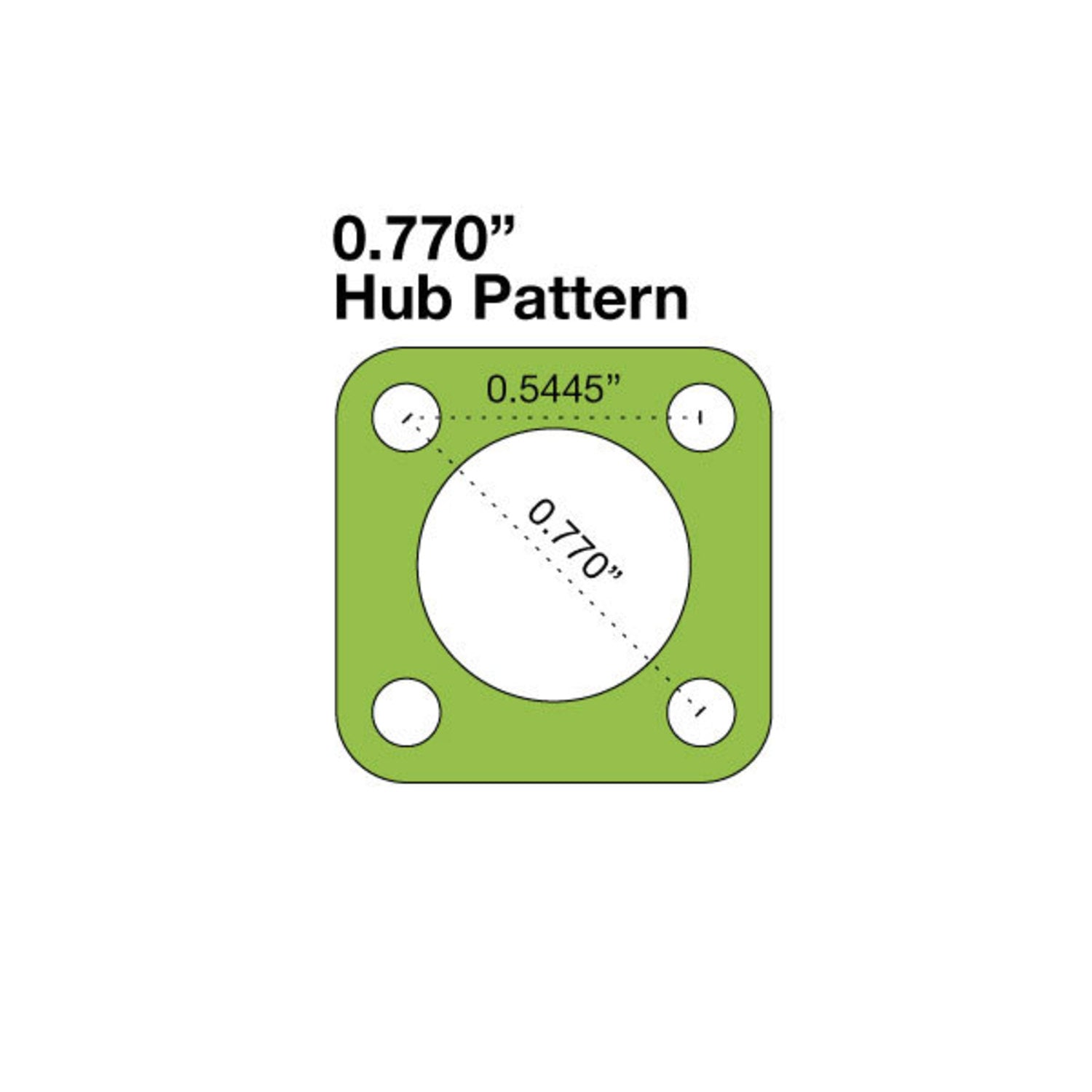

These channel gearbox kits with a standard 3.8:1 gear ratio feature threaded side mounts. This makes it a breeze to attach a standard - sized servo to various Actobotics products like tubing and channel. You can easily integrate a servo - powered gearbox into your custom pan & tilt, mechanical device, or robotic structure. The kit comes with a hardened 1/2” stainless - steel final shaft supported by dual ABEC - 5 precision ball bearings. It can handle up to 200 pounds of vertical and horizontal loads. The main spur gear is bolted to the drive hub, ensuring direct power transfer without slippage. Actobotics is a great robotics building system using extruded aluminum channels, gears, precision shafts, and ball bearings. Thanks to two standardized hole patterns, almost all Actobotics components connect intuitively. With a wide range of components, building complex electromechanical prototypes or finished projects is very achievable. Note: This gearbox kit doesn't include a servo. Check the related items for different Hitec servo options. Kit Includes: 1x Channel Mount Gear Box - 180° Rotation, 1x Hub Mount Gear, 1x 3.8:1 Servo Gear, 1x 0.77' x 0.77' Servo Hub, 1x ½' Clamp Hub, 1x 6 - 32 x 3/8' Set Screw, 4x 6 - 32 x ½' Socket Head Screw, 4x 6 - 32 x ¼' Phillips Head Screw. Features: Maximum Rotation - 180°, Gear Ratio - 3.8:1, Servo Size - Standard, Hub Pattern - 0.77'. Documents: Product Page (SPG400A - CM38), Assembly Instructions.

Using this gearbox kit is quite straightforward. First, pick a suitable Hitec servo as the kit doesn't come with one. Then, use the threaded side mounts to attach the servo to Actobotics products such as tubing or channel. Once it's attached, you can start integrating it into your custom pan & tilt, mechanical device, or robotic structure. When handling the kit, be careful with the components as they are precision - made. The hardened 1/2” stainless - steel final shaft and the ball bearings are durable, but avoid applying excessive force that goes beyond the 200 - pound load limit. For maintenance, keep the components clean from dust and debris. You can use a soft, dry cloth to wipe them down regularly. If you notice any signs of wear or damage, check the related documents or contact the support team for further guidance.