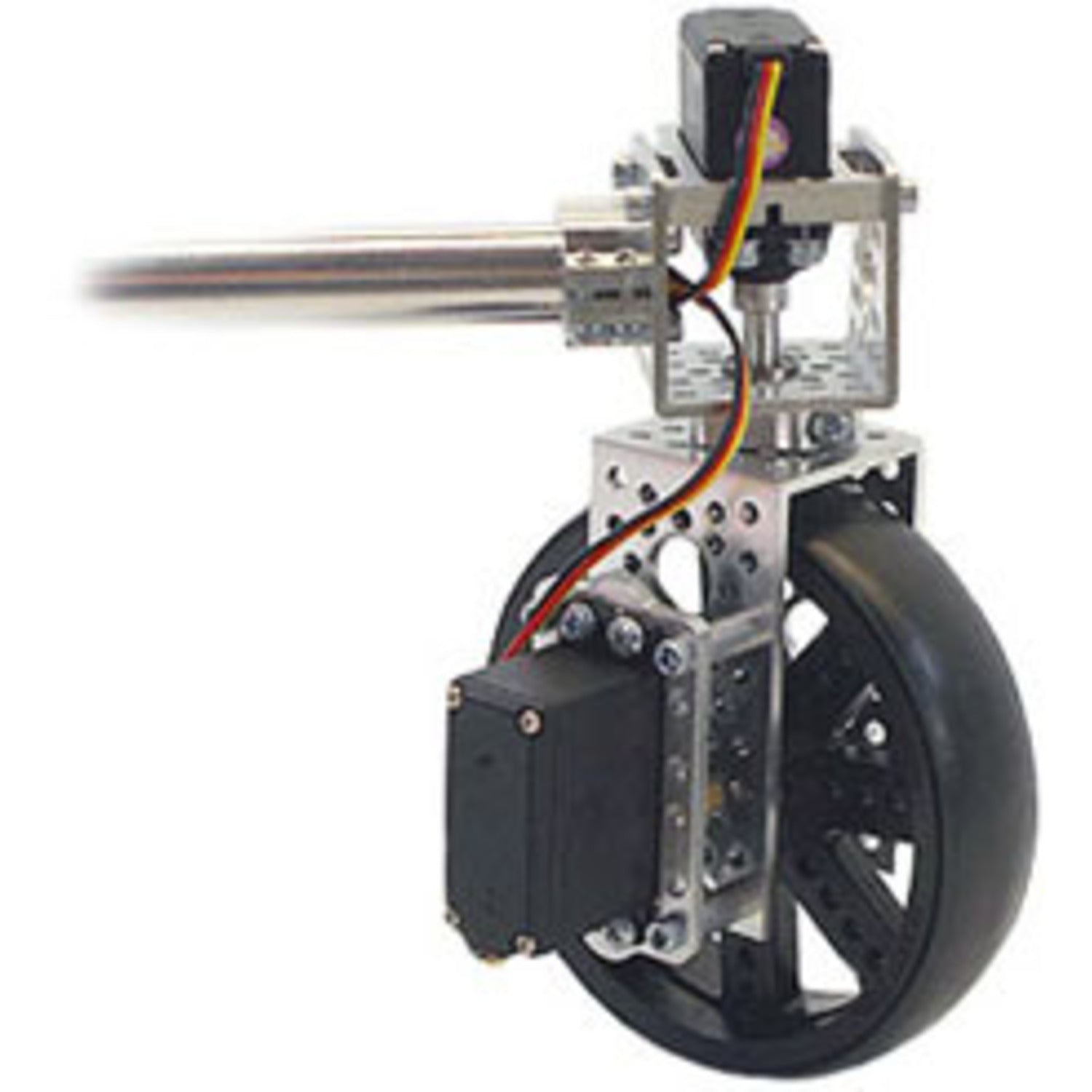

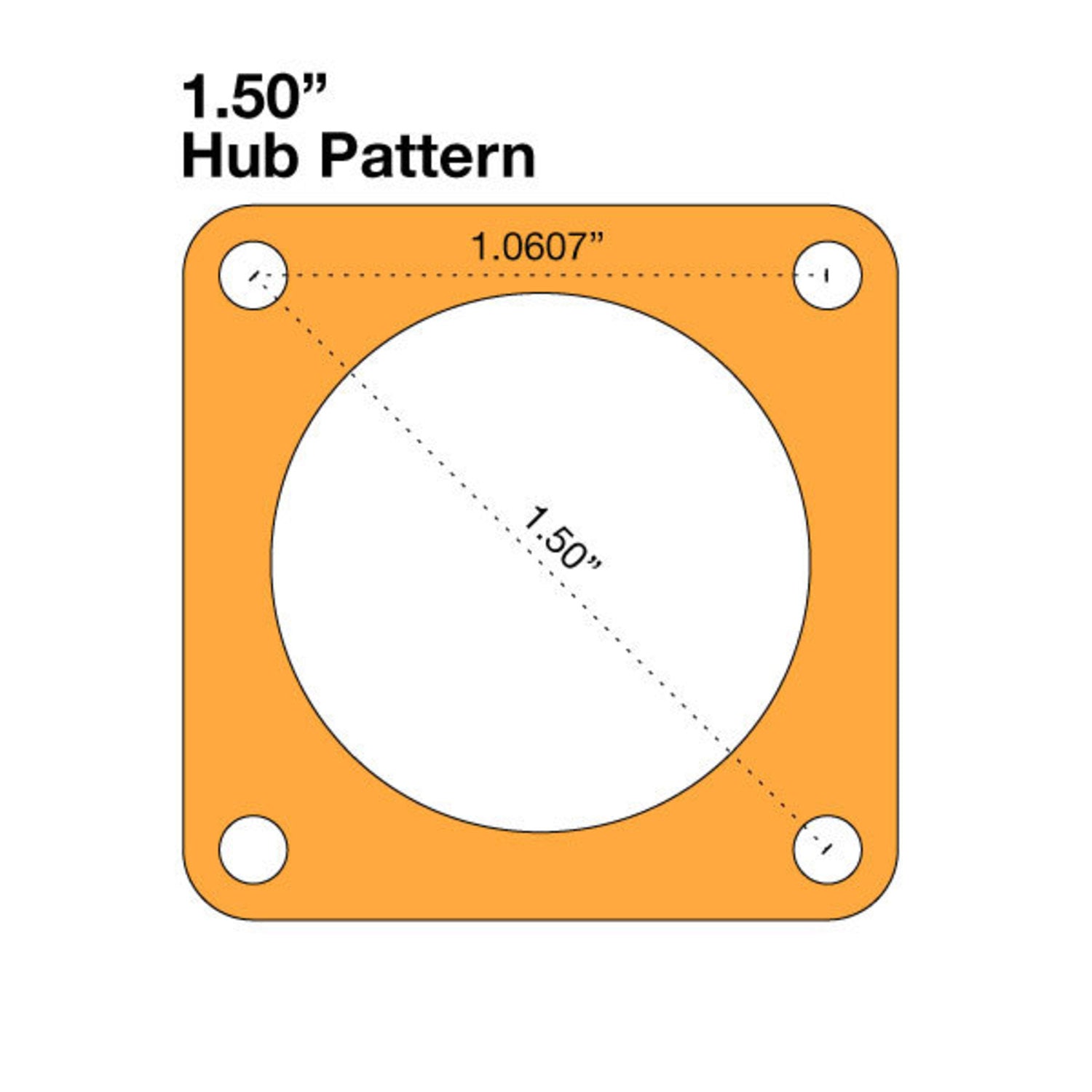

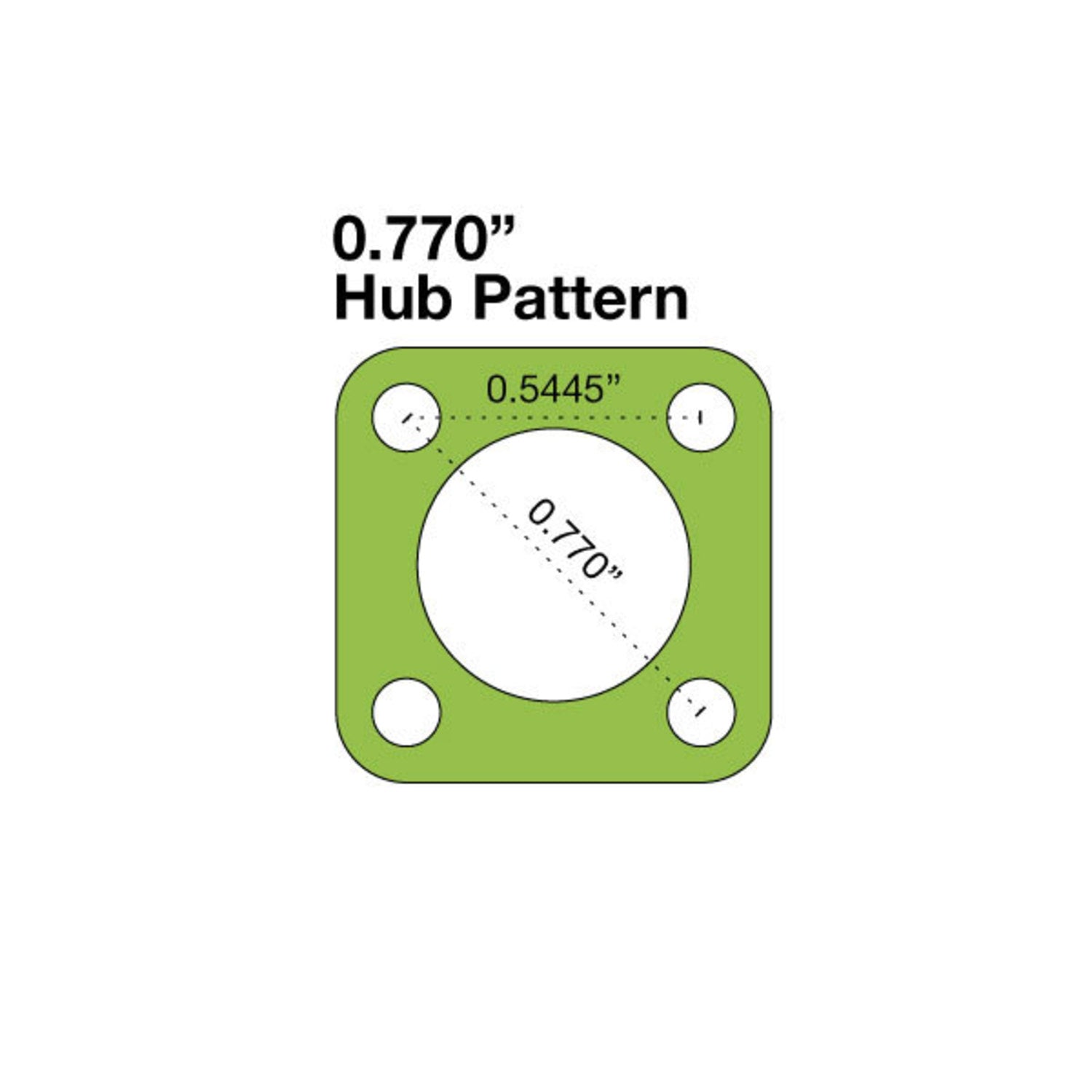

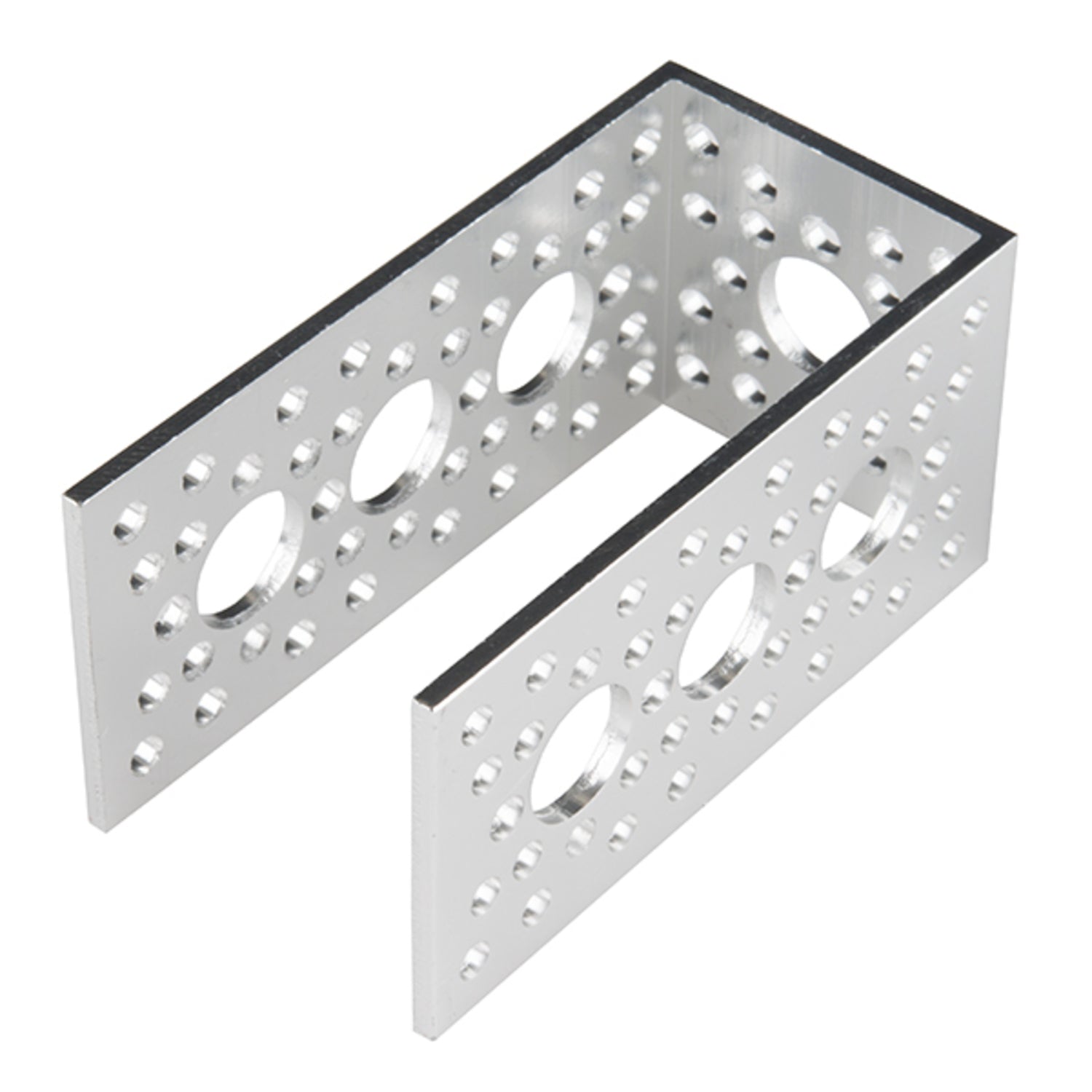

These heavy - duty aluminum channel brackets (Type A) offer a straightforward solution for connecting a robust wheel and motor to your electromechanical project. They can also act as connection points for servos, shafts, and other channels, with an easy - to - assemble design. Each bracket is 1.5' long, with exterior dimensions of 1.5' wide by 3' tall, interior dimensions of 1.32' wide by 2.91' deep, and a 0.09' thick wall. It uses both the 1.5' and 0.77' hub patterns. Actobotics, a robotics building system based on extruded aluminum channels, gears, precision shafts, and ball bearings, allows nearly all components to connect intuitively due to two standardized hole patterns. This wide - ranging component set makes building complex electromechanical prototypes or final projects achievable. Dimensions: Length - 1.5'; Exterior Dimensions - 1.5' Wide x 3' Tall; Interior Dimensions - 1.32' Wide x 2.91' Deep; Hub Pattern - 1.5' and 0.77'. Documents: SketchUp Part, Product Page (585484).

Using these channel brackets is a breeze. First, figure out where you want to place the bracket in your electromechanical project. You can use it to connect a heavy - duty wheel and motor or as a connection point for servos and shafts. Just align the holes according to the 1.5' and 0.77' hub patterns and fasten them securely. When handling, be careful not to bend the thin 0.09' wall. For maintenance, regularly check the brackets for any signs of wear or damage. If you notice any issues, replace the bracket promptly. Keep the brackets in a dry place to prevent rusting. This way, you can ensure they'll last a long time and keep your project running smoothly.