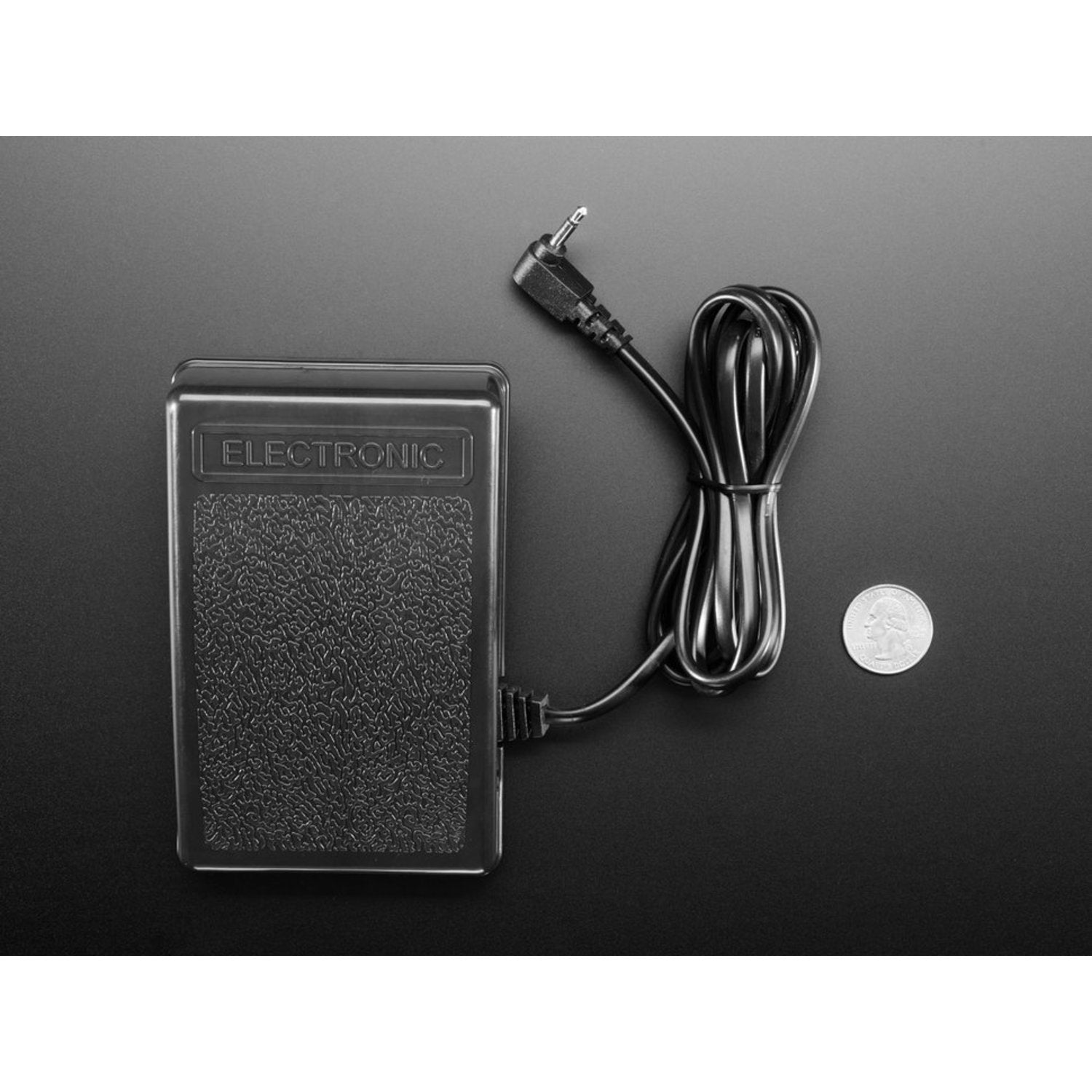

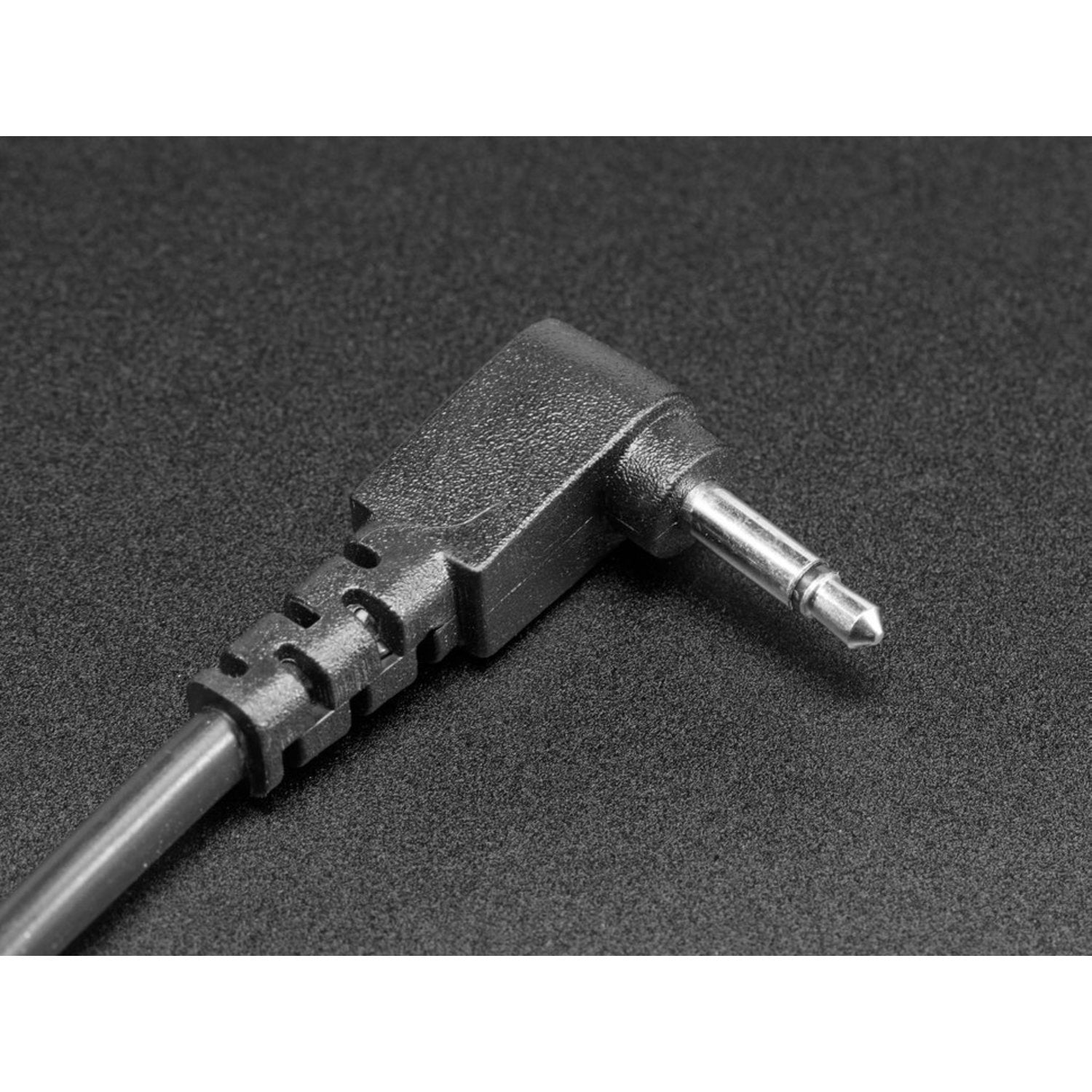

We've had a foot pedal switch in our store for some time. Many customers have reached out, asking if we could offer a way to retrofit it for variable speed control, just like a potentiometer. Well, here it is! This is a top - notch Foot Pedal Potentiometer, also known as a Sewing Machine Speed Controller. It's extremely sturdy and comes with a user - friendly 3.5mm 'audio' connector at the end, making it a breeze to integrate into your project. You can choose from a 3.5mm terminal - block adapter, in - line wired jack, breadboard jack, or a panel mount jack. Many cheap alternatives have a wall plug, low resistance (since they're designed for mains power), and aren't very durable. When you don't apply any pressure on the pedal, the resistance is about 20 KΩ. Press it all the way down, and it drops to about 1 KΩ, with a linear resistance change as you move the pedal. Connect one side to the ground and the other side to a 10K resistor that pulls up to your microcontroller's logic voltage. Then, read the analog voltage, just as you would with a photo - cell or other'resistive' sensors.

Using this foot pedal potentiometer is easy. First, you need to connect it to your project. Thanks to the 3.5mm 'audio' connector, you can pick a 3.5mm terminal - block adapter, in - line wired jack, breadboard jack, or a panel mount jack to make the connection. When it comes to the electrical setup, connect one side of the pedal to the ground. Then connect the other side to a 10K resistor, which should be pulled up to your microcontroller's logic voltage. After that, you can read the analog voltage, similar to how you would with a photo - cell. As for using the pedal, just step on it. When you don't put any pressure on it, the resistance is about 20 KΩ. Press it all the way down, and the resistance becomes about 1 KΩ. Remember, the resistance changes in a smooth, linear way as you move the pedal. As for maintenance, keep it clean and dry. Avoid using it in very humid or dusty environments, as this could affect its performance. And if you notice any problems, like a non - linear resistance change or a loose connection, check the wiring and connectors first.