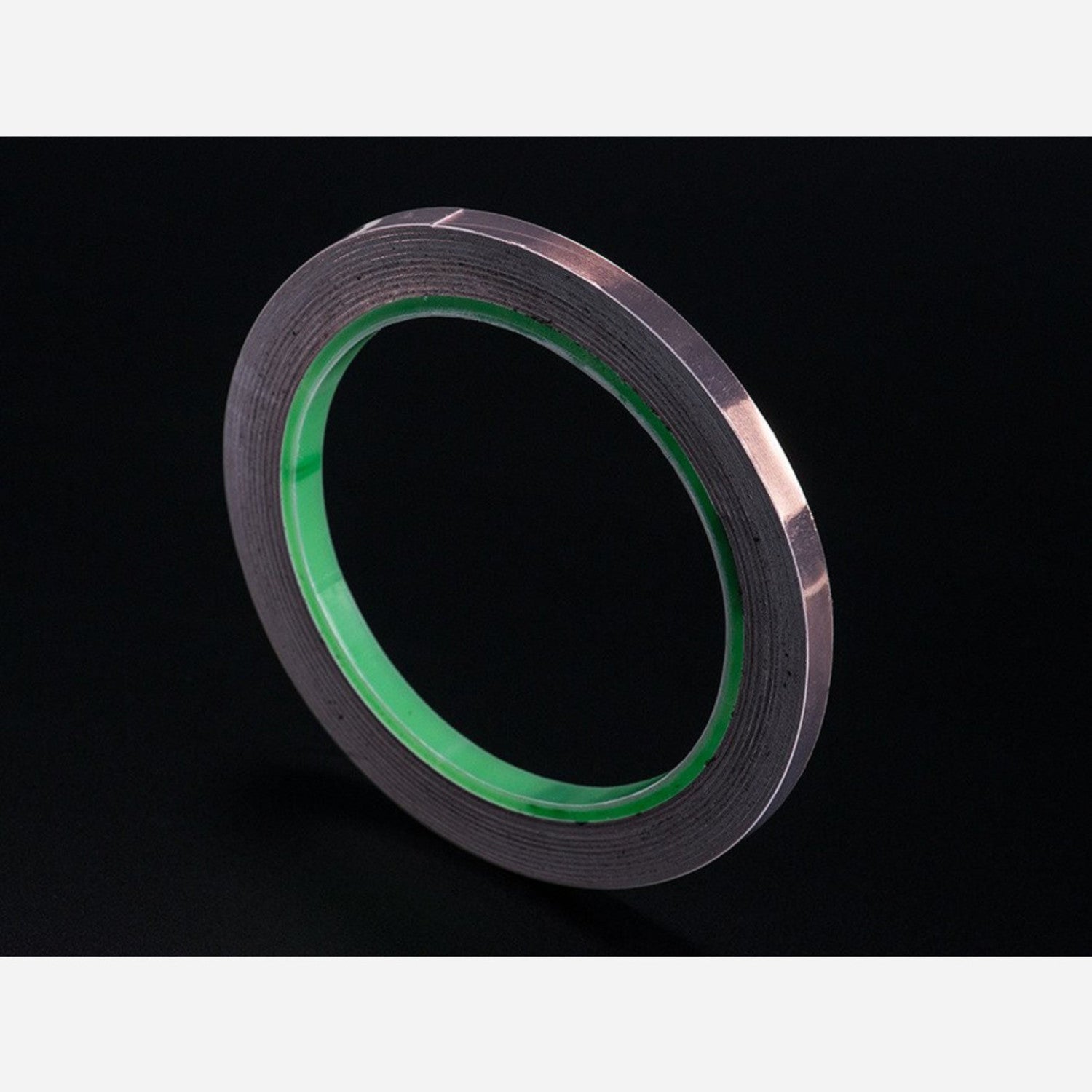

Copper tape is a must - have in your toolbox. Crafted from thin pure copper, it's incredibly flexible and can easily take on almost any shape. You can solder to it effortlessly, and it conducts electricity just like a wire. The back of the tape has an electrically conductive adhesive. While it can't carry a large amount of current, it's perfect for sensing applications where soldering isn't desired. This tape has many uses, such as EMI shielding, working with electroluminescent (EL) devices, making capacitive touch pads, and meeting ultra - thin wiring needs. It comes in a 15 - meter roll, is 3 mils (0.07mm) thick, 6mm wide, has conductive adhesive on one side, and a protective paper backing on the adhesive.

Using this copper foil tape is easy. First, peel off the protective paper backing to expose the conductive adhesive. Then, stick the tape to the surface where you need it. For EMI shielding, wrap the tape around the area you want to protect. When making capacitive touch pads, cut the tape into the right shape and attach it properly. Remember, while the adhesive can conduct electricity, it's not suitable for high - current applications. So, if you need to carry a large amount of current, use soldering. To keep the tape in good condition, store it in a cool, dry place. Avoid bending it too sharply as it may damage the copper. If you're using it in a damp environment, make sure to seal the edges to prevent oxidation.